CONSEQUENTIAL QUESTION

Can Energy-Intensive 24/7 Buildings Be Carbon-Neutral?

Fabian Kremkus, AIA

Design Principal and Healthcare Team Leader, CO Architects

December 11, 2024

CO Architects shares a case study – and answers a compelling question.

According to the U.S. Energy Information Administration (EIA), the average hospital consumes more than 100 times as much energy as a standard tract home. In effect, one hospital’s energy demands can exceed a 100-home housing tract. Hospitals are always open; they run on reserve-power generators during grid outages.

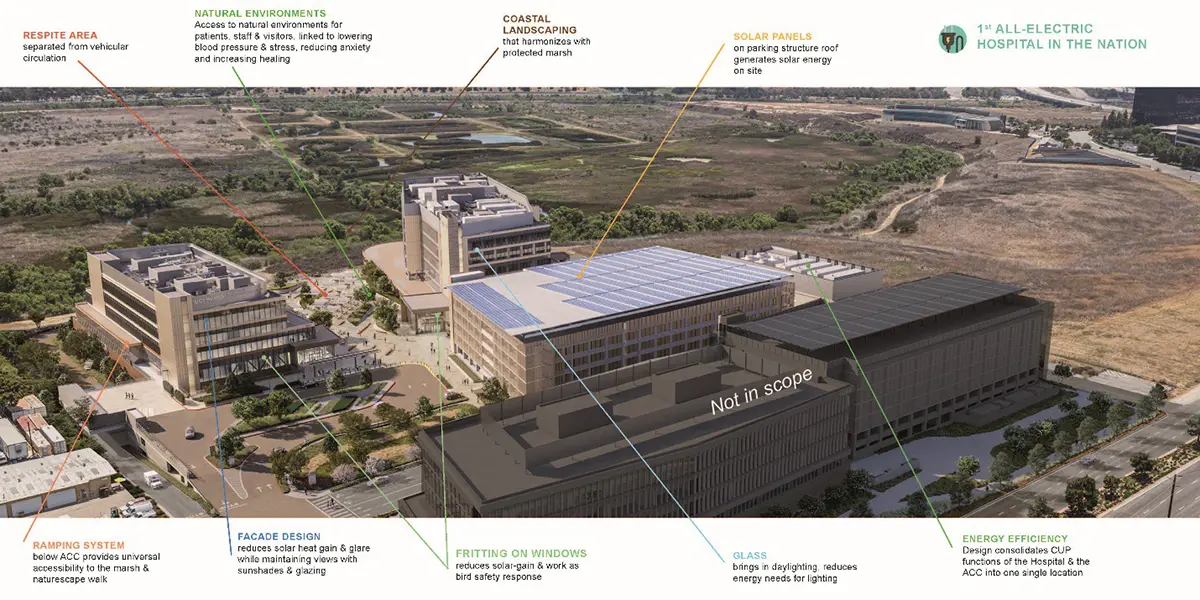

The University of California, Irvine, and UCI Health, with the design-build team from Hensel Phelps and CO Architects, are proving that hospitals and energy efficiency aren’t mutually exclusive. For the under-construction UCI Health – Irvine project adjacent to the university’s main campus, administrators chose to exceed California’s green-building standards and the University of California’s own minimum-LEED-Silver edict. In advance of California’s transition to 100% renewable energy, UCI administrators envisioned the country’s first non-fossil-fuel hospital, one of the first in the world.

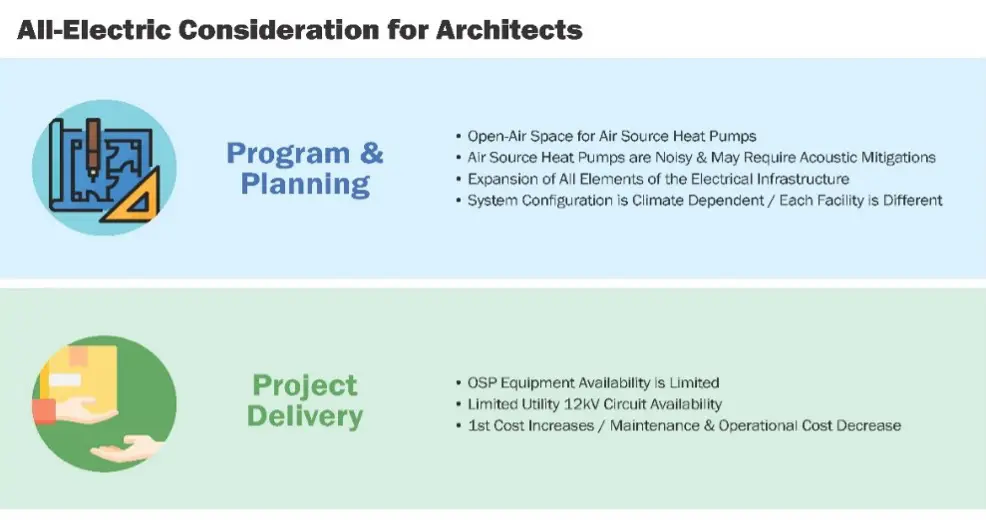

Being first places projects ahead of the curve for infrastructure and product innovation. From the outset, the UCI Health – Irvine plan exceeded the grid’s existing capacity. The all-electric goal necessitated upgrading the local utilities, a multi-year process that added an extra project planning element.

Similarly, we learned that ultra-high-efficiency HVAC products hadn’t been employed in projects of this scale. We couldn’t find a precedent for using heat pumps and recovery chillers in 600,000-square-foot, always-on projects.

As a result, this project presented a monumental design challenge. But since healthcare and sustainable design are two of CO Architects’ specialties, UCI Health – Irvine presented an opportunity to expand our expertise, and answer a consequential question: can a hospital be designed to be carbon-neutral?

Pushing the Envelope

The project site is adjacent to a marsh—a protected nature preserve. Prioritizing natural views from the project’s inpatient and outpatient buildings while controlling heat gain were design challenges from the outset. Full-height glazing was an early design goal to admit as much of the outside as possible, to foster a sense of peace and tranquility for patients, staff, and visitors.

Some twenty facade options were modeled. Our engineering partners, tk1sc/WSP, did extensive thermal-control simulations. The resulting unitized curtainwall solution became one of the project’s standout features: a combination of exterior sun-shading devices and glass frit patterns that reduce heat loads and discourage bird strikes. Full-scale mock-ups constructed by façade contractor Enclos were performance-tested at Smith-Emery Laboratory before finalizing the design.

Aesthetically, the frits emulate the Fibonacci sequence, a pattern found abundantly in nature. By introducing these abstract natural patterns into our architectural expression, the design team created a harmonious connection between the built environment and the natural world.

This comprehensive exterior shading strategy extends beyond the frit patterns to vertical and horizontal fins, trellises, canopies, and umbrella sculptures, which shade the facade and exterior waiting and amenity areas.

The unitized curtainwall combines full-height glazing for views of the marsh with Fibonacci sequence frits that progressively double in thickness. Functionally, the frits control heat gain and discourage bird strikes. (Tom Bonner/Courtesy CO Architects)

Courtesy CO Architects

All-Electric HVAC

Beyond providing visual and environmental comfort, this system of shading devices plays a vital role in managing the building’s thermal performance. By reducing solar heat gain and minimizing solar radiation gain, a cooler indoor environment results, limiting the need for artificial cooling and promoting energy efficiency.

At UCI Health – Irvine, the paramount energy challenge in the all-electric design was implementing non-fossil-fuel heat sources. Two such components are heat-recovery chillers and heat pumps. A traditional chiller generates chilled water and expels heat. Heat-recovery chillers operate by simultaneously cooling and heating water. Rather than rejecting heat to the atmosphere, heat-recovery chillers can provide the building’s heating and cooling requirements simultaneously, as long as a matching cooling load is available. Thus, UCI Health – Irvine’s central utility plant operates solely on electrical energy. This not only eliminates fossil fuels—even in the hospital’s kitchen—but also enhances the overall system efficiency.

Because the heating load can exceed the building’s cooling load at various times during the year, air-source heat pumps and additional traditional chillers are often required. An air-source heat pump can operate in heating- or cooling-only mode (some have a heat-recovery mode). For example, if more hot water is needed for heating, the heat pump will pull the heat from the outdoor air and create additional hot water—and vice versa for cooling. Compared to conventional fuel-burning HVAC systems and those with traditional electric boilers, a heat-pump/recovery-chiller system is as much as three times more efficient, making it an ideal all-electric HVAC solution.

Heat-pump systems present three primary building-design trade-offs: space, design, and cost. First, the system needs substantial space for equipment. The heat-recovery chillers need to be indoors, and the air-source heat pumps must be mounted outdoors. The heat pumps occupy significantly more space than traditional equipment and can be noticeably loud. Acoustical provisions must be part of the design equation.

Second, the project needs to be large enough to justify a central plant for the required chilled and hot water. UCI Health – Irvine’s plant is 35,000 square feet. System configuration is location-dependent—each project has its own design considerations based on its geography and weather patterns.

The cost for the all-electric heat recovery/heat pump system is significantly higher than traditional fossil-fuel heating. At UCI Health – Irvine, recovering heat from the steam generation required to sterilize hospital instruments will bring down the operational cost tremendously. Further, gas boilers need human oversight for safety reasons. Eliminating these boilers minimizes the facilities staffing demand. Looking ahead, system pricing will ideally decrease as demand and competition increase.

To further minimize utility power requirements, the entire top deck of the UCI Health – Irvine parking garage is covered in solar arrays, which generate significant quantities of renewable power. When the additional equipment costs are amortized over the project’s 100-plus-year lifespan, the initial higher first cost becomes marginal and pays back.

Forward-thinking design, procurement, and construction methodologies can lead to outstanding outcomes…

Embodied-Carbon Reduction

Reducing energy consumption minimizes the size of the generating systems, decreasing the embodied carbon. Early-stage strategic decisions on resource deployment with design-build leader Hensel Phelps were vital to leveraging the many synergies available to the project team. One embodied-carbon consideration was that the foundation slabs had to be thicker than initially designed. Environmental-impact insights required additional concrete to isolate UCI Health – Irvine from the adjacent San Joaquin Marsh.

To compensate, several framing designs were modeled. The solution: a buckling-restrained braces (BRB) design made from steel. This fulfilled seismic criteria and saved weight as compared to a moment-frame lateral system, reducing the structural embodied carbon impact by an estimated 15%.

The journey toward carbon neutrality for such an energy-intensive project was not without its challenges. The UCI Health – Irvine campus will be net-zero for operational carbon once the California grid converts to 100% renewable energy and phases out fossil-fuel power generation. (The emergency power is still diesel generator-operated and will never be carbon-free.)

A BRB structural design reduced embodied carbon by requiring 15% less steel. The compromise is slightly diminished interior layout flexibility due to diagonal bracing. (Tom Bonner/Courtesy CO Architects)

The Answer? Yes!

Our team’s commitment to environmental stewardship guided every decision. From the beginning, we focused on eliminating fossil fuels from all facility operations. This meant rethinking traditional systems and investing in cutting-edge technology that aligned with our sustainability goals.

The UCI Health – Irvine campus project is a shining example of how forward-thinking procurement and construction methodologies can lead to outstanding outcomes. When complete, the project will be a place where modern healthcare meets nature’s tranquility of, invites the outside in and connects us all to the wonderful biophilia that surrounds us—a carbon-neutral campus designed not just for today but to thrive well into the future.

Fabian Kremkus, AIA, is a design principal and healthcare team leader at Los Angeles-based CO Architects. With additional specialties in civic/cultural design and institutional interiors, he has practiced for nearly 30 years and joined CO Architects in 1999.