Profound Impact

by Sandeep Ahuja

Co-Founder and CEO, cove.tool

October 26, 2022

cove.tool co-founder Sandeep Ahuja discusses luck, timing, persistence and grit in enabling widespread change

DesignIntelligence (DI): We’re talking with Sandeep Ahuja, co-founder of cove.tool, a widely used, industry-leading building design and construction software tool. Welcome Sandeep.

Sandeep Ahuja (SA): Awesome. Thank you so much for having me.

DI: This is a timely conversation. Our editorial theme for this quarter at DesignIntelligence is impact; that is, how can built environment professionals generate and exert more influence? cove.tool is an illuminating study, maybe even the poster child of doing that. Can you share the story of how your product and your company came about? It might offer much for others who aspire to do similar things.

SA: Happy to talk about it. I’m glad you are covering this topic. I’ll start from where the inspiration came. It started back when I was a sustainability consultant, and before that, when I was a practicing architect. The fact was, it was hard to keep projects on budget, especially as we were collaborating across different disciplines, revisions, and design stages. In addition to that, we were tackling and battling changing energy regulations and ensuring everything was still working. We were not getting tons and tons of design revisions because, “Gosh, we had another value engineering exercise.” It was all driven first from a profitability standpoint and then combined with cost and survival viewpoints, “Let’s make this easier and simpler.”

That is exactly what gave birth to cove.tool. Within the practice itself, I was the person coordinating between the pre-construction team, the architecture team, the mechanical engineering team and the ownership team — getting them on the same page. Why? Because they all used different platforms and none of their tools actually talked to each other. As I was doing that manually with emails and Excel spreadsheets, I’d make one chart and show it to one group and say, “Hey, pre-construction team, this is the data we’re looking for?” And then I’d send that one to the mechanical engineering team and say, “Hey guys, we just need these values from you,” and then ask, “Hey architects, we just need these particular design decisions from you,” and then crunch it altogether and describe it to the owner, “Hey, this is the full story. This is what we’re looking at. This is how we’re going to get the project with all its requirements and nuances in budget.”

That process I just described — and its inherent time and value lags — is what we automated. Now, as we’ve continued to grow, that’s still the intent of what we do. We’re driving profitability and value by making creating and communicating information significantly easier for teams trying to get to energy code or trying to achieve LEED certification or trying to reach their performance targets or whatever their goals may be.

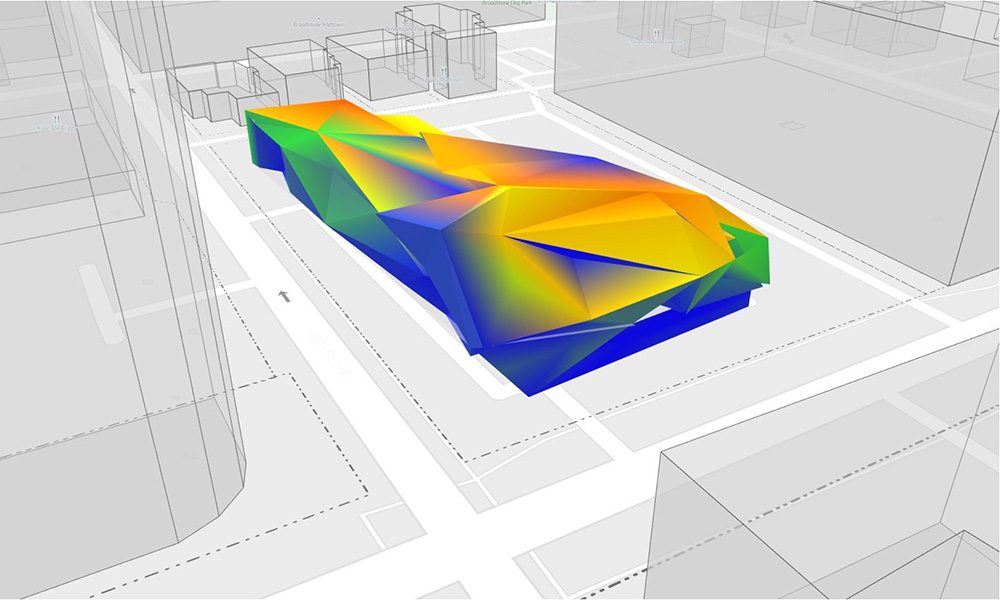

Image Courtesy: cove.tool

DI: We have much in common. I spent my career leading design teams in similar processes. Not just focused on sustainability but on the role of design management: connecting the designers and getting people to talk to one another. In many cases, translating information from one language to another. A hand-eye-machine process. You’re focused on doing that in the arena of sustainability and automating it intelligently.

SA: Yes. It’s a full-time job. It’s a real thing. It takes two to three weeks to get a cost estimate. It takes two to three weeks to get an energy model. It takes two to three weeks to get a daylight carbon model. If you’re trying to hit code and you spend three weeks getting your energy model and then another three weeks getting your cost estimate and you’re still trying to keep project timelines, you’re off to a bad start — losing weeks you never had using archaic workflow methods.

DI: You have a traditional architectural degree from Georgia Tech, an institute known across the world for its technical competencies and pedagogical bias. You just shared the challenges of integrating and communicating environmental options across a team, so perhaps necessity is the mother of invention. Where did your entrepreneurial spark come from? Was it a class, a mentor?

SA: I attribute it to two things. The first thing, I credit my entrepreneurial spirit to Georgia Tech. I’m a very proud Yellowjacket. The way the program helps us think outside the box and always challenge convention. It’s the only college websites I have seen where the home page says, “Come build your next startup.” They are so focused on the entrepreneurial spirit. “Hey, you can go do your own thing. You don’t have to follow convention. You don’t have to fall in line. You don’t have to do what people have done for the last 30, 40 or 50 years.” That’s a very Georgia Tech attitude and something I am wholeheartedly thankful for experiencing.

The other part is true for probably all entrepreneurs: Your risk meter has to be a little bit broken, and your desire to achieve something greater has to be very high. I always see business as a means to an end. I have to make the numbers, financials and economics work so I can keep pursuing my dream of reducing the carbon from all our buildings.

DI: Two strong clear sources. You didn’t venture outside the typical architectural curriculum?

SA: I was at Georgia Tech for my Master of Science in Architecture with a concentration in High Performance Buildings, which sits within the School of Architecture but also parallels with the School of Mechanical Engineering. There are a few classes with the opportunity to partner outside of architecture. For example, you could have a software engineer on the team and a mechanical engineer on the team in vertically integrated programs. I was able to participate in some of these classes, not just as a student, but later in life as an alumna and as instructor of that program. This collaboration is inspirational and the reason behind my testimonial: “Yes, this vertically integrated class inspired me and now I’m back to teach it to hopefully inspire one or two or three great ideas of the next century.”

DI: You’re back there teaching?

SA: I was, but now growing cove.tool is my full-time focus. When I started the business, I actually had a little bit more free time to teach, but now I am a very proud alumna who still goes back to visit regularly and stays connected with many of the faculty. I give back as much as I can with my involvement with selection committees and reviews from time to time, but growing cove.tool keeps me occupied.

DI: Let’s talk about timing. There are plenty of examples of people who invented the right thing at the wrong time, right time, wrong thing. Sadly, as long as 40 or 50 years ago, I’m aware of others who attempted to do what you do, to analyze energy and environmental design options. I was working at Heery International then, and they had a company doing it as early as 1981. The problem was the surrounding network and support ecosystem. We didn’t have computers like we have now. We were doing printouts on dot matrix computers. We couldn’t visualize it. The manual data entry was onerous. Now, for a decade or so, you’ve got all those things. You and your team, your software, through your wonderful opportunity at Tech and your own doing, is a great success story. Have you ever stopped to reflect on your good fortune and timing in the marketplace or maybe what might have been had that not been the case?

SA: Timing and good fortune are everything. I absolutely say it was the right time, the right place, and the desire so strong that I could not give up. But, from a timing standpoint, when we launched the software, the reason we have scaled 3x year over year is because there’s a strong need. There’s nothing sexy about energy codes. I didn’t pick something sexy to solve. I just picked something that absolutely needed to be solved on every single new construction and renovation project. There is no project that doesn’t have a budget challenge and every project needs to meet energy code. You have to hit both. The design teams are always trying to make sure they’re avoiding design rework and value analysis because profitability is always a challenge.

It’s needs-based. If I had launched 40 years ago, there was no energy code then, really. You could build whatever you wanted. It was just about budget: “How cheap can you get it?” There is no optimization when it’s just budget. You don’t have as many stakeholders and subconsultants. You’re just trying to make sure it’s the right price, and then the owners and architects are happy, and everything works.

The tighter energy regulations got, the stronger the need became. When the need became so strong that our business was thriving in Georgia, not the most energy conscious state, I said, “Well, that’s when you know it’s real. That’s when the need is strong.” That’s why we’ve grown, because there is demand. And it’s continuing to grow ... with all the latest regulations and the new Inflation Reduction Act getting passed. But it’s already strict. If you’re not doing energy and option analysis, you’re probably losing money. And if you are doing it, you might as well use a better workflow with some smart software.

But, yes, good fortune is everything. It’s also about finding the right people to help support you at the right time. The story of how I ended up finding my first mentor to guide me through the journey of building performance and thinking through the nuts and bolts of how stuff really works is a good example.

DI: Who was your mentor?

SA: The late professor Godfried Augenbroe. Unfortunately, we lost him last year.

DI: I’ve met Fried. A pioneer in building performance and a true gentleman.

SA: Oh, you knew Fried. Yes, I love him. I met him in Delhi. It was serendipitous. He was just visiting. I was thinking about going to the Georgia Tech program. I said, “Hey, I’m really excited about the program you’ve built. Would love to meet you but I don’t live in the United States.” I was living in New Delhi at the time. He said, “Believe it or not, I’m visiting next week. If you want, we can get together and figure it out.” I ended up meeting him in New Delhi and learned about his focus. He has been a pivotal force and my guiding light, in being able to determine what’s right from wrong, what matters versus not, because we can engineer until the end of everything, but he taught me to ask, “Is it worth it? Is it going to help you get the answer? If no, don’t bother.” Sound advice that has served me well.

DI: That’s wonderful you were lucky enough to have a mentor like him in your life. You have been selected from a cast of thousands to do this interview, for several reasons. The first is that our focus at DesignIntelligence this quarter is impact. The work you’re doing is all about measuring and delivering impact. Then, there’s the story of your company and its remarkable growth and impact on so many firms, projects and the environment. You just said you had three times growth annually and are repeating that?

SA: We’ll soon level off at 2x. We’ve got a good way to go until we issue our IPO.

DI: You’ve had astounding growth and profound impact in a very short time though your software. Can you share some data on your number of users or projects so we can get a feel for what you’re accomplishing?

SA: High level, there are multiple ways to think about impact. One way is the number of projects we have had the opportunity to influence. We’ve been able to touch over 25,000 projects in North America which is super exciting. There’s no way I could have done that as a consultant. It would’ve taken me a very long time to build a consulting practice to be able to do that many projects manually. It’s not just the number of projects that’s exciting but what that means in terms of carbon emissions. To date, projects cove.tool has optimized has resulted in offsetting over 30 million tons of carbon emissions. To put that in perspective, last year Tesla published their carbon emissions report that they offset five million tons. We did 30 million because buildings are responsible for 40% of all carbon emissions globally. Every building we help optimize helps reduce that impact.

DI: That’s incredible. What about growth projections? Your company is four years old. Give us a glimpse ahead: What are you projecting? Pick the metric you want: number of people, revenues … what are you seeing over the next few years?

SA: The metrics that matter to me the most are twofold. One is the number of projects we’ve influenced. We’ve done about 25,000 projects now. We want to get to about 100,000 in the next two years. Whether that’s renovation or new construction doesn’t matter, just projects we’re touching. We want to touch a total of 100,000 projects.

Alongside that is the carbon story. So far, we’ve offset about 30 million tons of carbon. We want to get to about 100 million tons of carbon offset in the next two years. That’s our two-year goal as we continue to scale. We’re currently a 75-person team. But growing the team is not necessarily directly tied to value. We’ll grow the team on an as-needed basis. Maybe we grow 2x. Maybe we have to triple. I don’t know, but I’m going to keep focusing growth with efficiency.

DI: Is your typical engagement just software someone is using on their own? Or are you providing consulting services along with the product?

SA: It’s software. All we do is make and sell software — and give great customer service. We’re very strong believers in customer success. For example, any of our software users, whether they’re a contractor like Skanska or a developer like Cousins Properties that may be on our platforms, we’ll have our dedicated customer success team to make sure they’re able to achieve success. We’re focused on imparting what it takes to make the project successful.

DI: Few limits on scalability then, because it’s software, not selling your time by the hour. Are there thoughts of new capabilities, different software modules, possibly selling services or products? Where are you looking?

SA: One of the most exciting areas we’re working on is for building product manufacturers. Now, we have thousands of architects and engineers using our software and deciding what products go into the building so contractors can take those specifications, pass those on to their subcontractors and eventually purchase them. But the decisions are getting made in the design development and construction drawing phases about what meets the energy code, embodied carbon and budget. Many of those decisions are getting made earlier on. We’re partnering with building product manufacturers to facilitate that information exchange in a smoother way.

For example, if I’m a building product manufacturer ... let’s say as an example, enVerid that makes a ventilation product, or Stora Enso that makes wooden beams ... and I’m trying to be able to say, “Use my product and it’s going to help you with carbon.” They’re able to quantify, in real time, for the architects, “It’s going to save you 40% on carbon. You should use this particular product versus whatever else you’re considering. And it’s going to be the most cost-effective way to do it because we just ran a cost optimization for you.” It brings the decision-makers and option providers closer, because, right now, that relationship is still in-person events like tradeshows and one-off events and quite old school.

I remember back when I was an architect. Building product representatives would bring cupcakes to the office and maybe do a ‘lunch and learn’. It was little more than, “Here’s my product,” and I’d have no way of knowing if I should use in my building. Can I see what it’s doing? Can you tell me exactly what it’s saving me? How do I know this is the right one? Why should I pick this product? Because you gave me some cupcakes? It was a manual, subjective, data-poor process. We’re changing that.

DI: That is exciting to hear you talk about leveraging the building product manufacturers. One of the great surprises to me was the failure of the building product manufacturers in an object-based BIM world. It never took off the way it was projected to. McGraw Hill, Dodge, Autodesk and many others were investing in this, but it seems to have died before it got started. The issues were about proprietary data in generic models. But geometry aside, you are now capitalizing on the power of the product data that was envisioned to be a part of that movement. Kudos to you for picking up that ball and running with it.

In architectural education, we’re taught that we are inventive and collaborative and yet are given no classes in those disciplines. Finding an architect with an entrepreneurial spark or a risk meter with range is rare. With the success you’ve had, do you ever get asked for coaching to have greater impact — either by traditional architects or related fields?

SA: All the time. Part of it is because of my upbringing. My dad was a diplomat. We packed our bags and moved to a new country every three years. Each time when we landed ... whether we were landing in Tanzania or in Saudi Arabia, my dad would say, “It’s going to be a new language. It’s going to be a new culture. It’s going to be new people. You go figure it out, kid.” That was the extent of his guidance. That stuck. No matter who I’m talking to, I know they’re going to have a different perspective from me and that’s okay. Just because it’s different doesn’t mean it’s right or wrong. It’s just different. We just need to figure out how to communicate better together. That’s the conversation I’ve had with so many in the industry: being able to communicate better.

When it comes to the risk part of it, I always say, “Do the math.” I did the math. “All right, this is how much it takes for me to live. If I am starting a startup, I’m not making money for a little while. How long can I do that? And just in case this doesn’t work, can I go get a job?” The answer was yes. The job is still there. The math worked. If the math didn’t work, I’d probably not do it, but the math worked. I convinced myself: “Fine. This makes perfect sense.”

DI: What a wonderful foundation for adaptation and risk tolerance. I learned late in life that we learn most from failures. I probably only made five major important decisions in my life, and they all worked out beautifully. On reflection, I look back and say, “I should have taken way more shots. I should have taken more risks.”

SA: But they all worked! You can’t be too upset about that.

DI: That’s true. But as architects, there’s something missing in our culture. We are afraid to take business risks and yet, unknowingly, we’re encultured to create risk everyday by trying new, untested designs without the benefit of research or data. What a dichotomy. The risk awareness is just not there. We’re comfortable playing in our design sandbox but not looking beyond it to assess potential risks.

SA: Yes. It’s either, “This has worked before. Let’s do it again,” or the default, “Let’s not reinvent the wheel,” but without the risk assessment.

DI: How do we help our brethren, our brothers and sisters — whether they’re traditional architects or people working in the support network on the fringes — how do we help them change their thinking and get better at leveraging their impact? Let’s say they’ve been through school already. They didn’t have that chance to see the world like you did. They’re stuck in a middle management position at a firm. What do you say to those people?

SA: Take a little risk. Take small risks. See what happens. If it works, then take a little bit bigger risk. It’s all about the math. I always do the math. Take a small risk if that’s what you’re ready for. What’s the worst that can happen? That’s how I look at things. Always. What’s the worst that can happen? If you’re okay with the worst that can happen, then it’s probably worth the risk. Then, you increase that a little and then a little more until you’ve built that muscle to always assess what’s the worst that can happen.

And what’s the best that can happen? It’s worth thinking about that too. Because a lot of times that’s significantly better than what you’re currently doing. The best that can happen is here and the worst that can happen, you just lose this much. The math is revealing.

DI: So simple. In my 20+ years working for a national construction management organization, I found, to a person, everyone in the organization was excellent at asking those questions. A stark contrast as compared to architects, who seemed oblivious to them. Somehow, in construction, it’s built into the culture and the type of people. Reflecting on your journey, what have been your biggest obstacles? And what has been most rewarding?

SA: Everything feels like an obstacle until you figure it out. When we first started, I had never raised capital before. I was a woman CEO. There are not that many women in the construction space and even fewer in the technology space. I didn’t know anyone who had raised capital before. My family, my friends, no one in my circle to ask, “Tell me how this is done so I can go do it.” So, I went to Georgia Tech’s Advanced Technology Development Center incubator program. It’s absolutely wonderful. Shout out to them. I got plenty of insight there but still had to figure it out much of it on my own. It’s early on when you have limited success when it’s the hardest. Because when you start being successful, you start developing a bigger broader network that continues to help you more. The very beginning was likely the hardest.

DI: At that point, the flywheel is turning, and people want to get on the bandwagon with you. You’ve got some wind behind you.

SA: People like success. They want to be associated with success and want to help, because they’ve now heard of me. If they don’t even know I exist, how can they figure out I need help — and that they can, in fact, help?

DI: As the wise, old CEO of an incredibly successful company of four years, what do those who wish to follow in your footsteps to create greater value and impact need to know most?

SA: What do you need most? It’s just grit. I don’t know what else to say. You just have to keep going and know in your heart there’s light. The first year I wondered, “Where is the freaking light? Come on, light. I’m ready for you! Let’s go!” You have to hang tight and convince yourself, “I believe this is going to work. These people may not believe me yet, but I know this is going to work.” That’s it.

In a tactical way, something I wish I could’ve told myself when I was first starting this business is to reach out more. I thought I didn’t have any mentors that could help me figure out how to raise capital, but I did. I just wasn’t reaching out to them well enough. I wasn’t persistent enough. I knew the top CEOs in Atlanta. Nothing stopped me from going to all the conferences they were going to, finding them and asking, “I would love to get 15 minutes of your time. Could I please get 15 minutes of your time?” Nothing stopped me from doing that. Just reach out for help and if you’re persistent, you’ll get it. I’ve gotten so many different mentors along the way. After my first year, I said, “I know what I need to do now.” With persistence, I’ve gotten mentors that I never could have imagined would make time to help my little company while we’re still growing. But when you ask people with kindness and they see you’re doing something cool, they’re very gracious. They want to help.

DI: Fantastic advice. I’m a late bloomer to networking, but the opportunity to have this conversation and talk to you ... I’m still learning wonderful things from you right now. Thank you so much for being here. You’ve been able to have a profound impact on so many projects — and the planet.

SA: This has been so great. I can’t thank you enough for the opportunity to do this. You are doing great things at DesignIntelligence and through your book. You have a lot to offer and it’s great that you are able to share it all so broadly. Thank you so much. I appreciate you.

Sandeep Ahuja is co-founder and CEO of cove.tool, the platform that is changing the way we create, communicate and exchange information for building design in the AEC.

Most recently, Sandeep presented at the UN environment assembly, with 1,500 global delegates, on the impact of building on climate change, showcased at the TEDx Atlanta and SXSW and honored as a Forbes 30 under 30. Sandeep’s impact in the AEC industry has been published in Forbes, Architect Magazine, Tech Crunch, Site Selection, ArchDaily and more. With her desire to bring automation into the AEC world, she is pioneering the integration of data driven thinking into the design and construction process through intelligent software.